Thursday 31 December 2015

Missing parts

Xmas holiday, family illnesses and some missing bits have kept this project on hold for a moment. I was about to assemble X and Z axises but the horrible quality of LM8UU put me off. I decided to order another batch of bearings from a different seller. Hopefully they will a bit better quality. I have been also waiting quite long some electrical supplies like heat protective sleeving and heat shrinking tube. Finally, those arrived today and I will be able to solder some of the wires soon.

Friday 4 December 2015

A4988 drivers and Vref adjustment

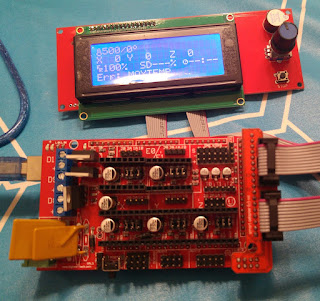

After verifying the LCD works I went forward with electronics. I placed the heat sinks on the A4988 drivers and plugged them on the RAMPS board. Based on the instructions and markings I placed them right way and started to think about Vref adjustment. This is for the motor current and I followed the instructions on the RepRapWiki. My drivers have Rs=100 Ohm and I wanted to start safe with 0.7A so I adjusted them to have Vref of 570mV.

A4988 drives with heat sinks

Marlin firmware

In order to get Arduino Mega clone and RAMPS board to function properly I need to install a firmware to Arduino. There are several choices but I decided to start with Marlin. It seems to be actively maintained and has good support.

I downloaded release version 1.0.2 and started to work with the configuration file. I did not modify too many settings at this point. I only selected correct motherboard settings and enabled LCD support. After uploading the firmware I disconnected Arduino and pressed the RAMPS board on it. I also hooked up the LCD screen cables and powered everything up. The LCD lit up and the menu was operational so I guess it works ok.

I downloaded release version 1.0.2 and started to work with the configuration file. I did not modify too many settings at this point. I only selected correct motherboard settings and enabled LCD support. After uploading the firmware I disconnected Arduino and pressed the RAMPS board on it. I also hooked up the LCD screen cables and powered everything up. The LCD lit up and the menu was operational so I guess it works ok.

Thursday 3 December 2015

Electronics arrived

We had a postal strike here in Finland so not much happened for a while. But today I got some packages! My Arduino Mega clone, RAMPS and bunch of other stuff arrived.

I have an original Arduino UNO so the Arduino IDE was already familiar to me. I'll leave installation of the electronics for the weekend but I wanted to test the Mega board first. But it did not work straight away with OS X 10.9. The simple LED blinking code refused to upload to the board. The error was following:

avrdude: ser_open(): can't open device "COM1": No such file or directory ioctl("TIOCMGET"): Inappropriate ioctl for device

So after a couple searches I learnt I should install a new USB driver. The instructions and driver can be found here: http://kiguino.moos.io/2014/12/31/how-to-use-arduino-nano-mini-pro-with-CH340G-on-mac-osx-yosemite.html

After running the installer and reboot the Arduino IDE was able to upload the code and LED blinker works fine now.

I have an original Arduino UNO so the Arduino IDE was already familiar to me. I'll leave installation of the electronics for the weekend but I wanted to test the Mega board first. But it did not work straight away with OS X 10.9. The simple LED blinking code refused to upload to the board. The error was following:

avrdude: ser_open(): can't open device "COM1": No such file or directory ioctl("TIOCMGET"): Inappropriate ioctl for device

So after a couple searches I learnt I should install a new USB driver. The instructions and driver can be found here: http://kiguino.moos.io/2014/12/31/how-to-use-arduino-nano-mini-pro-with-CH340G-on-mac-osx-yosemite.html

After running the installer and reboot the Arduino IDE was able to upload the code and LED blinker works fine now.

Saturday 21 November 2015

Lubrication and hammering

Finally I cut most of the 8mm smooth rods. First I tried with hacksaw with bimetal blade but that was just polishing the shaft. So I ended up using Dremel with 0.4mm cutting wheel. Actually several wheels as they were some no-name cheap ones and many of them shattered. A good reason to use safety glasses.

With Y-axis rods done I was able to try out LM8UU the bearings. As mentioned earlier, I bought some very cheap ones and they definitely behaved like that. Replacing them with better ones or with IGUS is on my todo. I cleaned up the linear bearings and lubricated them with lithium based grease. As an afterthought the grease might have been a bit too thick and sticky for such small bearings.

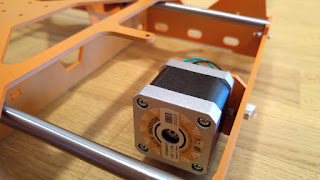

After hammering the rods in place I also installed the first stepper motor. I bought a package of five stepper motors and they are all ACT Motor 17HS4417. They should be ok but I will see later how they perform. I don't expect very high acceleration for Y-axis as the build plate carriage is quite heavy even without any heatbed or glass. I will attach the belt as soon as I get some more printed parts for the carriage.

With Y-axis rods done I was able to try out LM8UU the bearings. As mentioned earlier, I bought some very cheap ones and they definitely behaved like that. Replacing them with better ones or with IGUS is on my todo. I cleaned up the linear bearings and lubricated them with lithium based grease. As an afterthought the grease might have been a bit too thick and sticky for such small bearings.

Y-axis rods in place

After hammering the rods in place I also installed the first stepper motor. I bought a package of five stepper motors and they are all ACT Motor 17HS4417. They should be ok but I will see later how they perform. I don't expect very high acceleration for Y-axis as the build plate carriage is quite heavy even without any heatbed or glass. I will attach the belt as soon as I get some more printed parts for the carriage.

17HS4417 in place

Friday 20 November 2015

Bearings

Pile of LM8UU

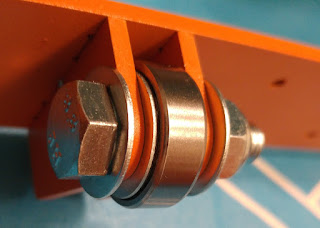

Both LM8UU and 608ZZ bearings arrived and I have installed one bearing so far. Y-axis idler was the only one that does not require 8mm shafts to be cut and ready. I went through 608ZZ bearings and selected the one that did not feel like having gravel inside. No issues here, except I didn't have M8 bolt and nut so a quick run to local hardware store was required. I might replace this with smaller bearing as in Toolson design.

Y-axis idler

Monday 16 November 2015

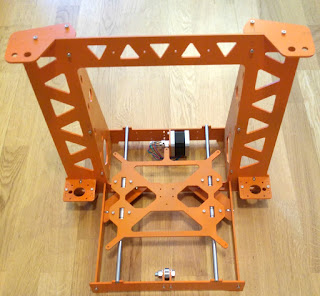

Final painting and some assembly

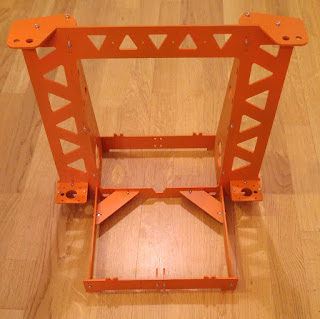

Alright. Orange is the color. I painted the orange color on Sunday and this time I did have a tiny bit better place to do it. I went to my brother's garage to change winter tyres and to paint the frame in the corner of it. The garage was rather full of motorbikes and cars so I had to be careful with spraying. I used a Maston colormix spray can but I don't really recommend it. Also the temperature inside was only +12. And I ran out of paint. So as you might guess the end result was not very good - a combination of dust, dry paint and runny paint. I don't say I hate many things but painting with poor setup, in a hurry and with bad quality tools is one of them.

Today I put together all the frame parts I could. I am still waiting bearings to arrive so I could not proceed with any of the axis yet. But at least I have received M5 brass nuts, stepper motors, GT2 pulleys and belt.

Oh, by the way - did I say I hate painting?

More or less orange

Today I put together all the frame parts I could. I am still waiting bearings to arrive so I could not proceed with any of the axis yet. But at least I have received M5 brass nuts, stepper motors, GT2 pulleys and belt.

Oh, by the way - did I say I hate painting?

Wednesday 11 November 2015

8mm smooth rods

I believe good quality rods are essential for the printer operation so I decided to skip cheapest ones. I bought Cf 53 h6 8mm HRC 60-64 rods from SKS. The price was around 14e per meter and I bought enough for two printers and some spare. At the moment long rods are waiting to be cut to correct length. Today I had just enough time to wipe them with Anti-Corrol gun oil before storing them away.

Oh, and date is 11.11 so I ordered bunch of electronics from AliExpress.

Oh, and date is 11.11 so I ordered bunch of electronics from AliExpress.

Enclosure planning

While waiting some parts to arrive I have been thinking what kind of enclosure this printer will get. There are several reasons to have one and most of them are related to safety. I am planning to have HEPA and carbon filter for the exhaust in order keep the fumes and particles in minimum. The enclosure also serves as a sound proofing and depending on material and design some fire protection might be achieved. Naturally the temperature can be controlled better inside enclosure and this should improve print quality on ABS and some other materials.

I happen to have a spare Arduino Uno which will became the controller of the printer main relay. The actual printer hardware like RAMPS, Steppers and heated bed are powered by 12V line through that relay. Arduino Uno will monitor temperature readings and keep the relay closed only if values are within safe limits. It will also control enclosure exhaust fan speed in order to maintain desired enclosure temperature.

The design and materials of the enclosure are still undecided. Most likely something like a 50 x 50 x 50 cm cube with door on one side.

I happen to have a spare Arduino Uno which will became the controller of the printer main relay. The actual printer hardware like RAMPS, Steppers and heated bed are powered by 12V line through that relay. Arduino Uno will monitor temperature readings and keep the relay closed only if values are within safe limits. It will also control enclosure exhaust fan speed in order to maintain desired enclosure temperature.

The design and materials of the enclosure are still undecided. Most likely something like a 50 x 50 x 50 cm cube with door on one side.

Tuesday 10 November 2015

Painting the frame

Test assembly after couple layers of primer

Spray painting with aerosol cans is not my favourite hobby as the results usually are poor. To make things even more complicated it is rather cold and damp outside so I have to wait to get access to a decent indoor painting area. Bathroom does not work as the paint dust tends to wander out and trigger fire alarm. In the middle of the night of course.

Friday 6 November 2015

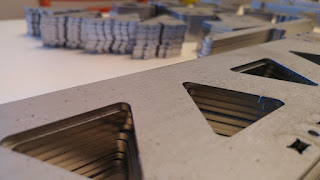

Laser cut frames arrived

Today I received the laser cut frames of the P3Steel V2.5 DXL. Material is 3mm structural steel S355 and parts were ordered without any further finishing after the laser cut. This means there is a little bit of cleanup, sanding and painting to do. I ordered 10 sets and at the moment there are six frames available all the frames were gone or reserved within ten days.

In the next couple of days I will clean up my frame and prime it. The final color will be selected and painted after the main frame assembly is done as I don't want to scratch the shiny new surfaces.

Parts stacked and counted

In the next couple of days I will clean up my frame and prime it. The final color will be selected and painted after the main frame assembly is done as I don't want to scratch the shiny new surfaces.

Monday 2 November 2015

Power supply modification

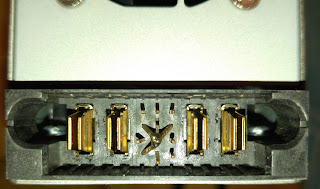

My HP DPS-600PB B arrived today and I managed to modify it to supply 12V without additional hardware attached. The modification is really simple and requires only basic soldering skills, no need to open the PSU enclosure.

Before anything else I plugged the unit in. The fan started to rotate but no 12V output. The next step was to unplug it, heat up the soldering iron and solder pins 4, 6, 8 and 10 together.

Then I powered up the unit again and I measured 12V outputs again. Now I got nice 12.5V without load. I did not invent this myself - these units are very popular among RC hobbyists and all kind of modifications have been created. I was happy to get 12V 47A with 30 euros. I still need to come up some decent connectors for outputs and I might remove the handle and the red locking tab.

http://www.rcgroups.com/forums/showthread.php?t=2371780

http://www.rcgroups.com/forums/showthread.php?t=1581061

HP DPS-600PB B

Before anything else I plugged the unit in. The fan started to rotate but no 12V output. The next step was to unplug it, heat up the soldering iron and solder pins 4, 6, 8 and 10 together.

Pins 4, 6, 8 and 10 soldered together. Two ground connectors on the left and two +12V on the right.

Then I powered up the unit again and I measured 12V outputs again. Now I got nice 12.5V without load. I did not invent this myself - these units are very popular among RC hobbyists and all kind of modifications have been created. I was happy to get 12V 47A with 30 euros. I still need to come up some decent connectors for outputs and I might remove the handle and the red locking tab.

http://www.rcgroups.com/forums/showthread.php?t=2371780

http://www.rcgroups.com/forums/showthread.php?t=1581061

Friday 30 October 2015

NEMA 17 Stepper motors

The printer requires 5 stepper motors. X and Y axis use one each, Z is using two and one for extruder. I spent way too much time figuring out what kind of stepper motors I would get. Based on the information and advices I found, I tried to choose reasonably priced, under 2A stepper with close to 0.44 Nm holding torque. I was trying to make my mind up between 42BYGHW609 and 17HS4417. Both have very similar specs but I was able to find 5 pcs located with 53e shipping included from Germany instead of China. So they should arrive a bit sooner and no need to pay tax or custom fees.

Thursday 29 October 2015

Bearings, belts and pulleys

I have ordered bunch of bearings, GT2 belt and pulleys from China. The quality of those bearings will be a mystery but I have an idea to replace some of the LM8UU bearings with printed or IGUS bushings later on.

The most difficult part to find is a good set of round smooth linear rods. I would like them to be chromed stainless steel and preferably correct length. I think Y axis of P3Steel can accommodate longer than specified rods but all the others should be spot on. I don't really like the idea of cutting 8mm chromed bar with Dremel.

The most difficult part to find is a good set of round smooth linear rods. I would like them to be chromed stainless steel and preferably correct length. I think Y axis of P3Steel can accommodate longer than specified rods but all the others should be spot on. I don't really like the idea of cutting 8mm chromed bar with Dremel.

Wednesday 28 October 2015

M3 nuts and screws

P3Steel is using M3 screws and nuts almost everywhere and there are three different lengths for screws. The amount of screws required is around 80 pcs so price matters here as well. I have been trying to source parts as locally as possible but I did not manage to find reasonably priced ones. Local stores stock only M5 or larger and specialist shops have a bit silly prices.

I ended up ordering the set of 100 pcs M3 Nyloc nuts, 80 M3 screws with different lengths and 20 M3 washers from UK. Bolt Base Ltd has a nice selection online with reasonable prices. In case of using their ebay store, remember to ask combined shipping price.

I ended up ordering the set of 100 pcs M3 Nyloc nuts, 80 M3 screws with different lengths and 20 M3 washers from UK. Bolt Base Ltd has a nice selection online with reasonable prices. In case of using their ebay store, remember to ask combined shipping price.

Monday 26 October 2015

Power supply options

Basically, there are three or four options for a RepRap power supply. A laptop power brick is an easy and safe way but the max power is usually too low for printer with a heatbed. One could get a separate brick for heatbed, though.

A bit more common approach is to use ATX power supply. Unfortunately I don't have any spare ones around and a new quality ATX providing 30A 12V is not free. Second hand ATX I found were generally too old and weak.

LED strip power supply is pretty cheap compared to its power but the quality varies and I really don't like the idea of wiring the mains socket to terminals and somehow securing them from accidental poking. As I have little kids running around this alternative is ruled out.

Now, after reading about this topic for a while I came across an idea of using server power supply. These are high quality units meant for 24/7 use. They come with safe mains connection and they output more than enough power on 12V lines. I decided to buy a second hand HP DPS-600PB B 575W which provides 47A on 12V. The best part is the price - 30 euros delivery included.

I will post more details about this PSU as soon as I receive it.

A bit more common approach is to use ATX power supply. Unfortunately I don't have any spare ones around and a new quality ATX providing 30A 12V is not free. Second hand ATX I found were generally too old and weak.

LED strip power supply is pretty cheap compared to its power but the quality varies and I really don't like the idea of wiring the mains socket to terminals and somehow securing them from accidental poking. As I have little kids running around this alternative is ruled out.

Now, after reading about this topic for a while I came across an idea of using server power supply. These are high quality units meant for 24/7 use. They come with safe mains connection and they output more than enough power on 12V lines. I decided to buy a second hand HP DPS-600PB B 575W which provides 47A on 12V. The best part is the price - 30 euros delivery included.

I will post more details about this PSU as soon as I receive it.

Frame sourcing

The frame of the P3Steel is 3mm structural steel. RepRap site hosts DWG file for couple different versions and the parts are neatly laid ready for laser cut. I chose version 2.5 by AndrewBCN as it supports dual extruders better than earlier designs.

So I decided to send request for offer to several laser cutting companies nearby. I got good amount of replies and now going through details with the cheapest one. Most likely I will order a set of 10 frames or so. I hope I will eventually find other P3Steel builders so I won't end up storing plates of steel in my living room for very long.

Introduction

This is a build blog of a RepRap P3Steel 3D printer. It will cover the steps from sourcing the parts to assembly and printing.

http://reprap.org/wiki/P3Steel

http://reprap.org/wiki/P3Steel

Subscribe to:

Posts (Atom)